What is IEC 60228?

The IEC 60228 is an international standard published by the International Electrotechnical Commission (IEC) that defines a set of standard wire cross-sectional areas for insulated cables.

Key Points:

- Current Version: Third Edition published in November 2004.

- Purpose: Standardize wire sizes for consistent electrical performance.

- Focus: Defines cross-sectional areas instead of diameters.

- Benefits:

- Simplifies wire selection based on electrical properties (resistance, current capacity).

- Ensures consistent performance regardless of slight variations in wire diameter from different manufacturers.

Why Cross-Sectional Area?

- Easier to relate to strength, weight, and resistance compared to diameter.

- Directly proportional to current carrying capacity.

Standard Sizes:

The document specifies a range of standard cross-sectional areas, including:

- 0.5 mm² to 10000 mm²

- Larger sizes in increments of 200 mm² (up to 2500 mm²)

Additional Information:

- The document also defines conductor classes based on flexibility and temperature rating.

- It specifies the minimum number of strands for stranded conductors (Class 2) and the maximum diameter of individual strands in flexible conductors (Class 5 & 6).

- Defines the maximum permissible resistance per unit length for each conductor size, class, and type.

Importance of IEC 60228:

- Provides a universal language for specifying wire sizes based on electrical characteristics.

- Ensures consistent performance and simplifies design and manufacturing processes globally.

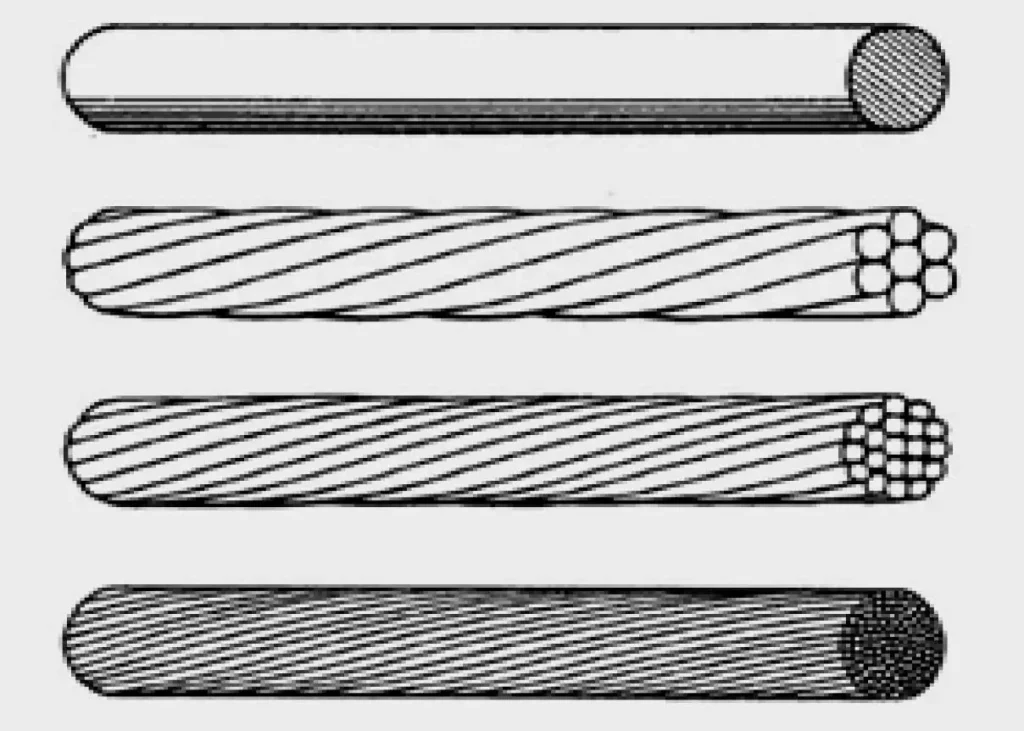

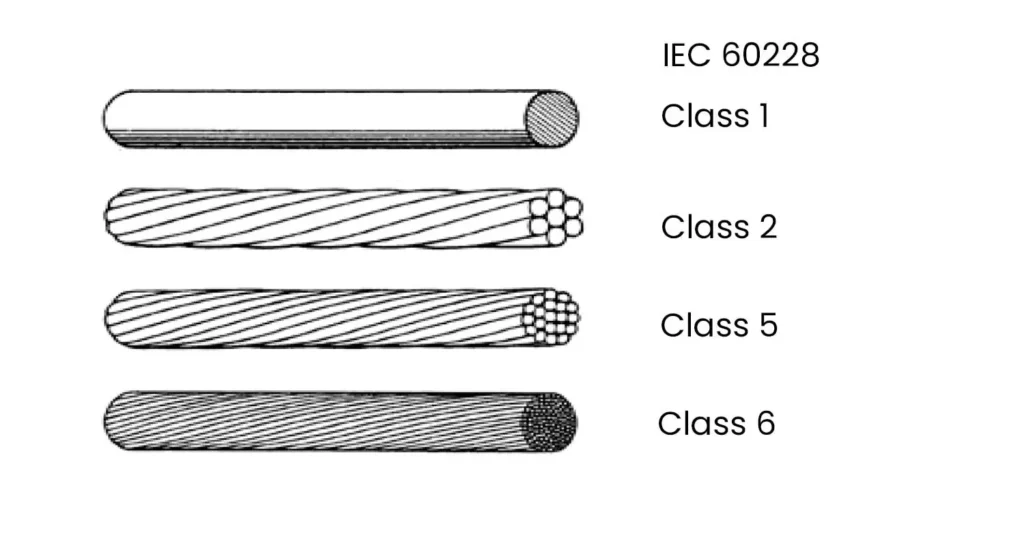

There are different types of conductors based on their flexibility:

- Class 1: Solid conductors (U): These are single, rigid wires used for cables with a diameter up to 6 or 10 mm². They are suitable for fixed installations where flexibility is not crucial.

- Class 2: Stranded conductors (R): These are formed by multiple thin wires twisted together, making them more flexible than solid conductors. They are used for larger diameter cables (> 6 or 10 mm²) in fixed installations where some bending is required.

- Class 5: Flexible conductors: These are highly flexible cables made of many thin wires, ideal for applications requiring frequent movement or bending, such as power tools and appliances.

- Class 6: Very flexible conductors: As the name suggests, these are the most flexible type, with an even larger number of thin wires for maximum flexibility. They are used in demanding applications where extreme bendability is necessary, like portable electronics and medical equipment.